Podcast: Play in new window | Download

One of the great things about owning a CNC machine is that you can easily turn ideas into a small side, or even a full-time business. Once you learn the basics, all it takes is a little creativity and you can make not only crafty projects, but items that can be purchased by people as a keepsake or heirloom to remember times shared with loved ones on vacation. This is exactly what Chris Rauch has done with his business, Studio Creative, located on Cape Cod, Massachusetts.

Chris is a full time mechanical engineer and navel architect developing underwater robotics systems used for science applications and defense work. Having owned a CNC machine shop in the past, Chris new the possibilites that he could realize by owning a CNC machine with the ability to start a side business with the help of his son to create custom souvenirs for the tourists that visit Cape Cod each year.

Chris owns a STEPCRAFT D.840 CNC system with a MM-1000 Spindle and Automatic Tool Changer. He also purchased his system with the DL-445 Laser attachment so he can quickly change from laser projects to CNC milling/cutting projects.

Photos of Projects that Chris Made

Laser Engraving

Very small detailed engraving

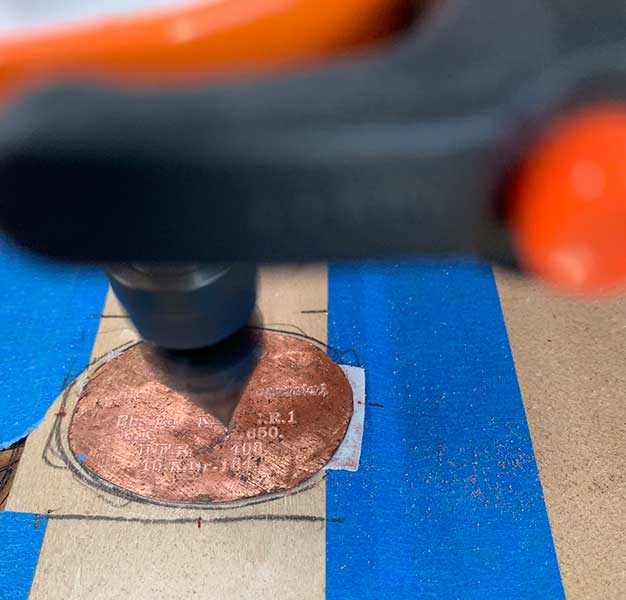

Machining mold for carbon fibre part

Finished Carbon fiber part

Carbon fiber part as it came out of the mold

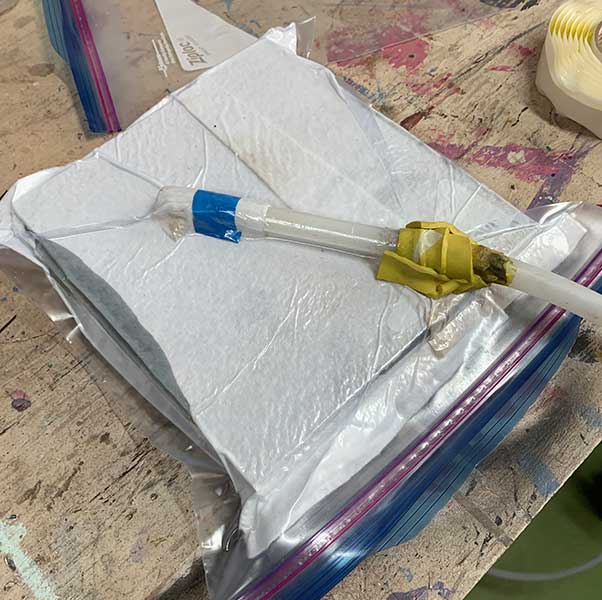

Carbon fiber part curing in a vacuum forming fixture

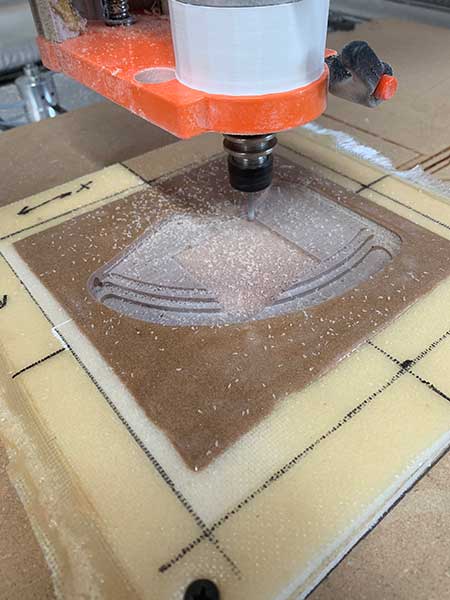

Machining a mold

Anchor Notebook made from veneer

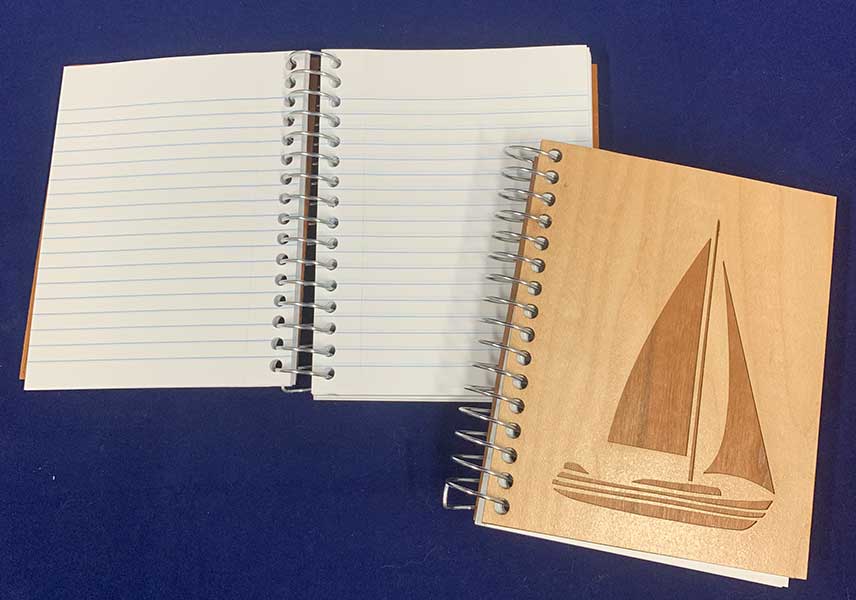

Sailboat notebook made from veneer

Products Mentioned in this Episode:

Amazon Canvas – www.amazoncanvas.com

Vectric Software – www.vectric.com

Stepcraft CNC – www.stepcraft.us

Amana Tools – www.amanatools.com

FS Wizard App – www.fswizard.com

Tips From This Episode:

Copy A Tool For Multiple Uses

Sometimes you have a tool that you use in different materials where each tool is has different feed and speed settings. You can make this easier by making copies of the tool in the Vectric tool library and simply rename the tool for the material or application that you have it setup for. Example, “1/8″ 2 Flute UpCut Endmill (For Pine)” and “1/8” 2 Flute UpCut Endmill (for Cherry). Then you can have different feed and speed settings for each. This can also be used with a Laser where you can assign different power and speed settings for various materials.

Monitor Exact RPM on Manual Spindles And Routers

Using a simple optical tachometer can allow you to set the exact RPM that you need on your manually-controlled spindle or router. This will also allow you verify the exact RPM for fixed speed routers so you can enter that info into a speed/feed calculator to get the proper settings for your project. All you need is to order a Tachometer like this:

You simply need to paint a white stripe on your collet nut with paint or even liquid paper and point the laser dot from the tach on the collet and you will instantly get a real time RPM readout for your spindle.

Download Amana Tool Vectric Tool Configuration Files

Amana Tool has made it easier than ever to get the correct feed and speed settings into Vectric for your projects. You can click on the “Vectric Library” but on most tool pages and download the file for that tool to be imported into your copy of Vectric software. Our experience has been that the setting are very close on most machines.

Use G54-G59 Work Offsets to Quickly Reference Datums On Your CNC

There are a lot of cases where you want to quickly move your XYZ location to a specific point on your machine, whether it be the exact center, lower left or some other location based on a fixture you are using to machine a job. Using G54-G59 work offsets will allow you to store and quickly recall these locations. I suggest using G55-G59 for custom settings but leave G54 as your “normal” project work offset location which you can change from job to job.

Take A Photo Of Your Machine DRO Settings

If you do not use work offsets, you can take picture of the machine DRO settings with your smartphone prior to running a job so in the event something happens (lost steps, or lost power), you can manually enter in those XYZ coordinates in the MDI by recording DRO machine settings in case you need to reset a start point on your CNC.

Example:

G00 = Rapid linear move

example: G00 X## Y## Z## (X,Y,Z = position)

Use Foam Insulation For Practice

The blue, green or pink rigid foam board that you can get from big box stores like Home Depot or Lowes is perfect material for practicing CNC projects when you are a beginner or if you are testing something very complicated for the first time. Foam will give so you are less likely to break a bit in the event of improper CAM settings but it is stable enough to see the actual result of what a project will cut like, even to the point of test fitting parts into the cut object.

Contacts

Chris Rauch (Guest) – Chris@creatorkits.com

Erick Royer (Host) – erick.royer@stepcraft.us

Thanks for sharing all of your experiences!

Thank you so much for the comment – I am happy to do this podcast for everyone – Erick